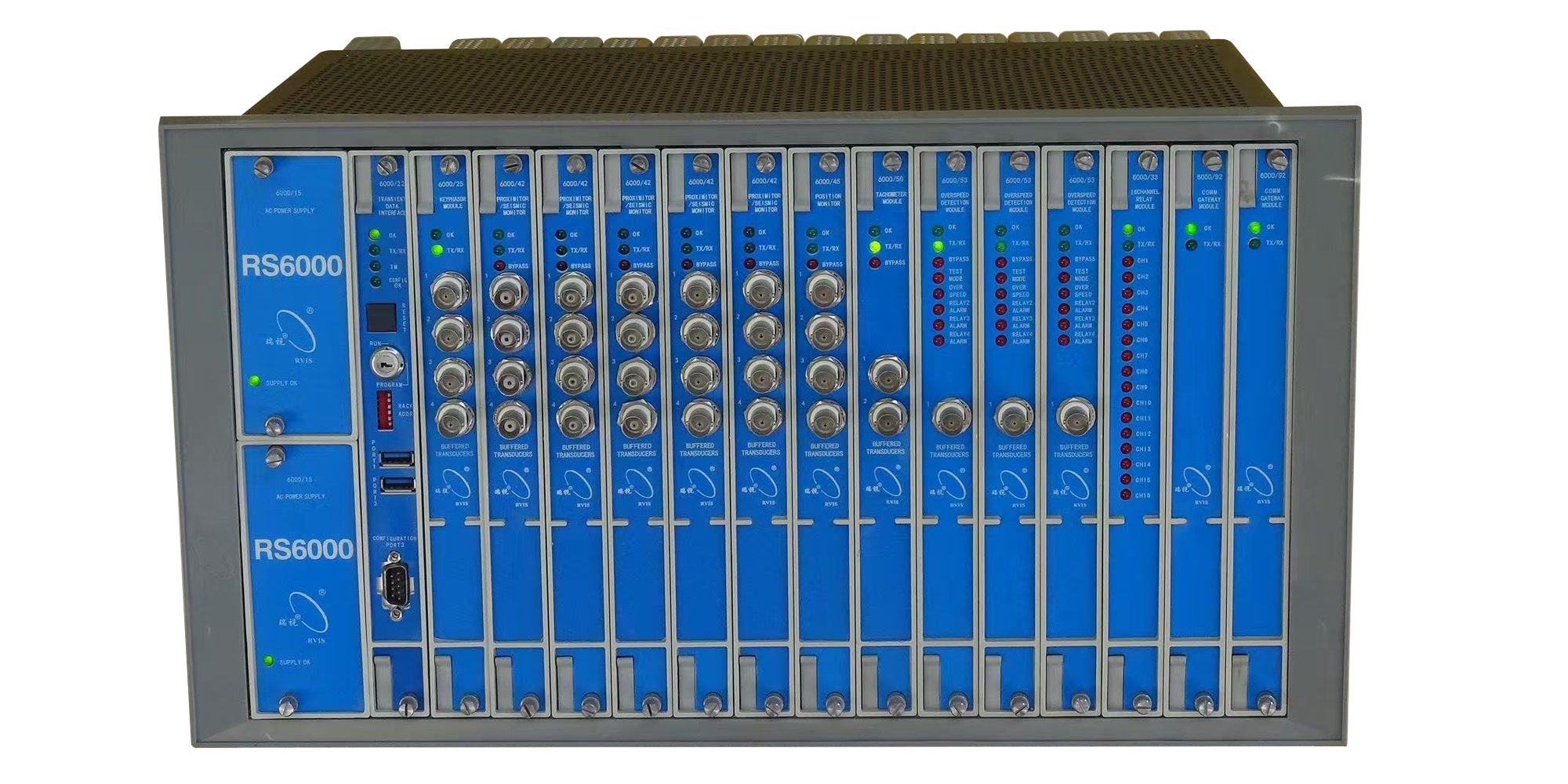

■RS6000/05 combined frame chassis.

(19 inch opening size: the size of 446×250 is equivalent to Bently 3500)

(12 inch opening size: the size of 270×250 is equivalent to Bently3500)

■RS6000/15 system power supply (dual power supply redundant design).

The power card is a half-height module and must be installed in a specially designed slot on the left side of the frame. The RS6000 device can be equipped with two power supply modules, any one of which can supply power to the entire device, and the other serves as a backup redundant power supply.

High voltage AC power supply: 175 ~246VACrms low voltage AC power supply: 85 ~132VACrms

■RS6000/22 is equipped with master control module with acquisition function (standard static data acquisition, transient or dynamic data acquisition).

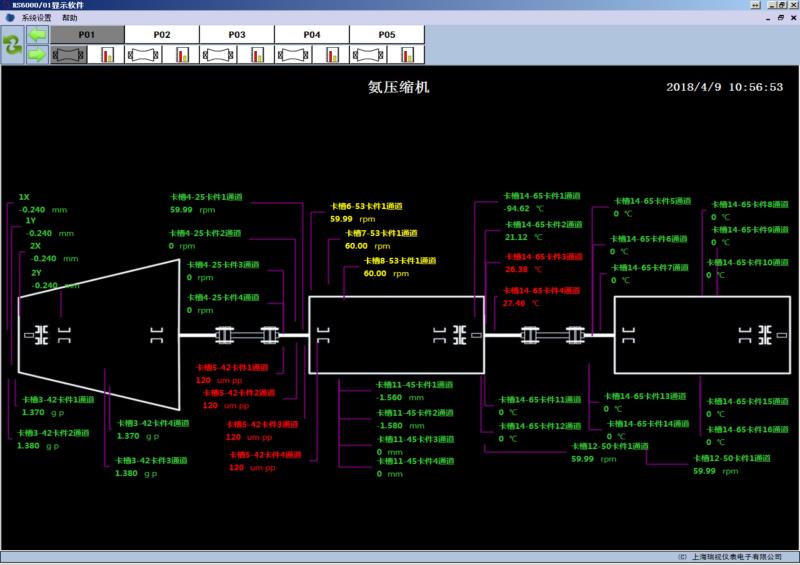

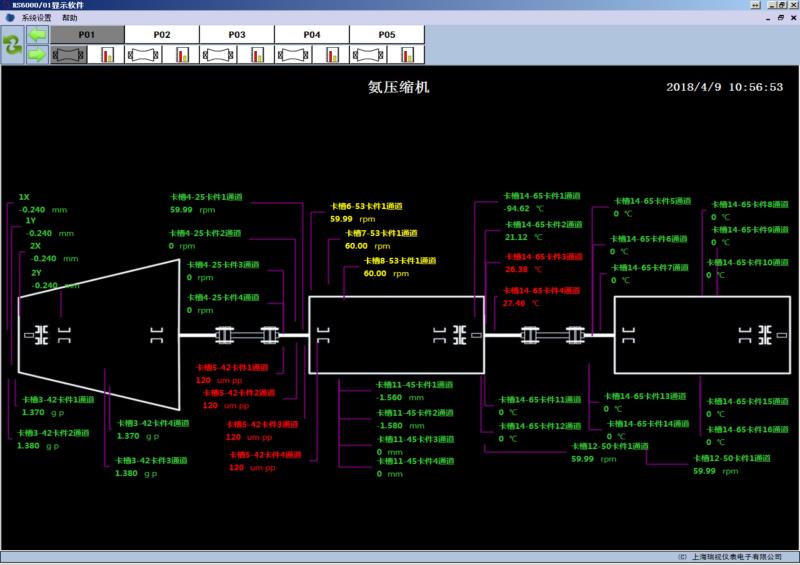

It can manage each sub-board, display data and communicate with the host computer, and perform static, transient or dynamic data collection. It also can directly communicate with the fault analysis software of the upper computer.

■RS6000/15 key phase module; 4-channel input.

It is used to provide the key phase signal for the monitor module in the RS6000 module, accept the input signal from the eddy current sensor or the magnetoelectric sensor, and convert this signal into a digital key phase signal, which can indicate when the key phase mark on the rotating shaft passes through the key phase probe to provide a standard for synchronous whole-cycle acquisition.

■RS6000/42 displacement / speed / acceleration monitoring module; 4-channel input.

Receives signals from eddy current sensors, piezoelectric / magnetoelectric sensors and acceleration sensors, completes various vibration and displacement monitoring, and drive alarm relays to realize mechanical protection. It can be configured to realize the monitoring functions of shaft displacement, shaft vibration, vibration acceleration, vibration speed, bush vibration, differential expansion, and thermal expansion.

■RS6000/32 relay module; 8-channel input.

8-channel relay module output, independently programmed, to perform the required voting logic. Each relay applied to the 8-channel relay module has "alarm driving logic", which can be programmed by "AND gate" and "OR gate" logic, and can provide alarm input (warning or danger) by using any monitor channel or any combination of monitor channels in the device.

■RS6000/33 relay module; 16-channel output.

16-channel output relay module, independently programmed, to perform the voting logic required. Each relay applied to the 16-channel relay module has "alarm driving logic", which can be programmed by "AND gate" and "OR gate" logic, and can use the alarm input (warning or danger) provided by any monitor channel or any combination of monitor channels in the frame.

■RS6000/45 differential expansion / axial displacement monitoring; 4-channel input.

The 4-channel differential expansion / axial displacement monitoring module can realize the monitoring functions of axial displacement, differential expansion, standard / non-standard single slope differential expansion, double slope differential expansion, compensating differential expansion and shell expansion (thermal expansion), and can realize the above two functions at most. Continuously compare the monitored parameters with the set alarm points and drive the alarm.

■RS6000/50 speed monitoring module; 2-channel input.

2-channel speed module, which receives the signals of eddy current sensor and magnetoelectric sensor (active and passive), can determine the speed of shaft, the acceleration of rotor or the direction of rotor, and compare with the set alarm point to drive the alarm. With peak holding function, when storing the highest speed, it can also be configured to provide key phase signals for other monitors.

■RS6000/53 overspeed protection monitoring module; Single channel input.

Redundant tachometer system with high reliability and quick response is used for overspeed protection. To realize the 2-out-of-2 voting system, 2 RS6000/53 modules must be selected; To realize the 2-out-of-3 voting system, three RS6000/53 modules should be selected.

■RS6000/65 temperature monitoring module; 16-channel temperature monitoring

Resistive temperature sensor (RTD) or electric couple sensor (TC) can be accepted. According to these input signals, the alarm settings can be driven and record output can be provided.

■RS6000/92 communication gateway module

The monitoring data and condition of all monitoring modules are integrated with process control and other automation systems through Ethernet TCP / IP and serial (RS232 / RS422 / RS485) communication protocols.

■RS6000/93 display module

Query each monitoring module and display data.

Sensor / Transmitter Technology

Sensor / Transmitter Technology